Inert Waste

Who Are We?

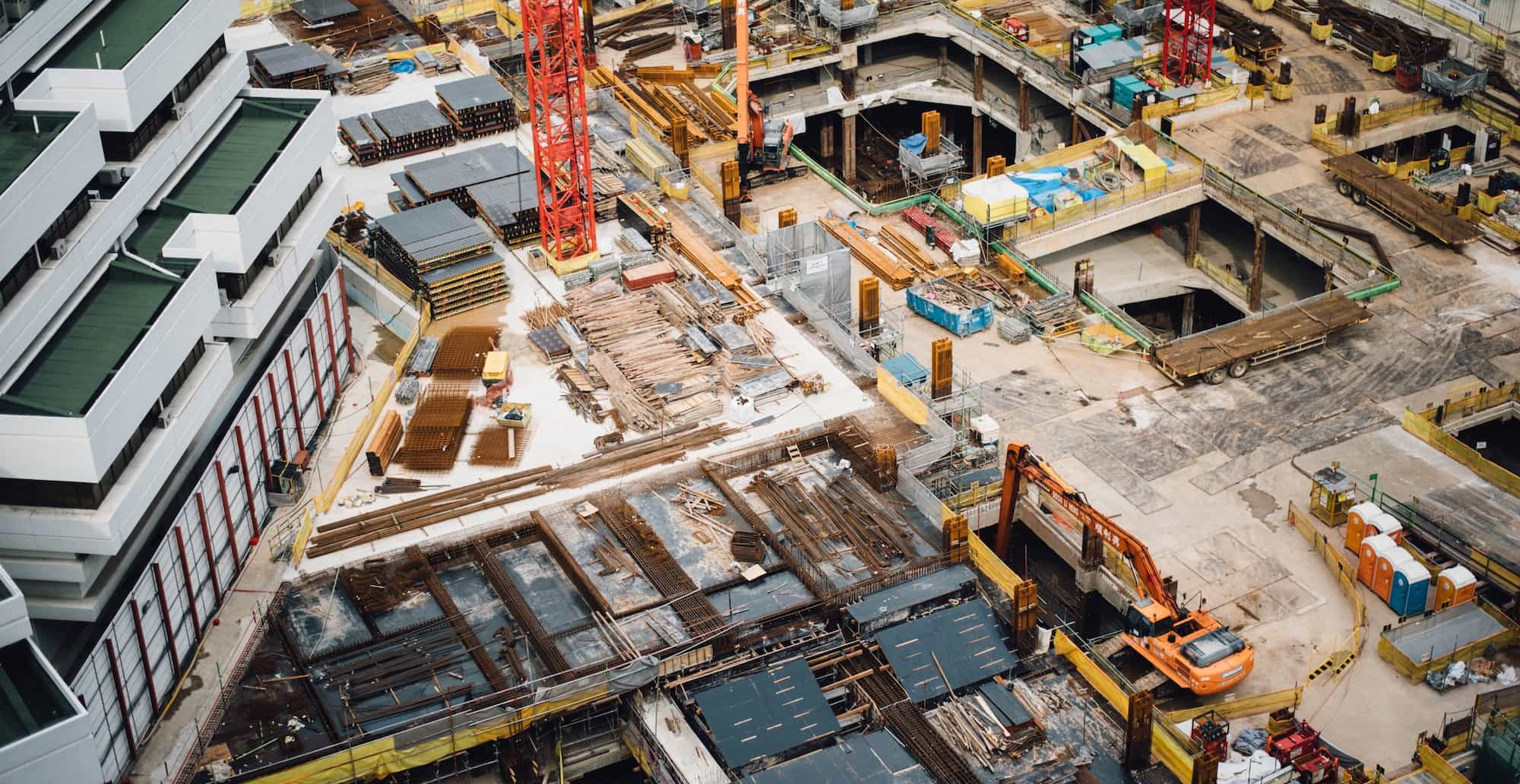

Virtus Concrete’s key offering are sustainable concrete blocks called Blockwalls, manufactured from 87 per cent recycled materials comprising mainly low-value inert waste materials.

The blocks are assembled to build structures instantaneously without the need of expensive joining techniques or intensive labour hours. They can be used on any number of construction projects including civil engineering, flood defence, security and construction.

Our Product

Virtus Concrete is a bespoke pre-cast geopolymer concrete product manufacturer and solutions provider with a focus on civil, groundwork and infrastructure projects. With a patent-pending design, the company provides a stacking solution that has a unique reinforced design which allows the blocks to be installed to a height of over 8 meters, almost double the height of any other block provider.

The geopolymer block is made from glass recovered from recycling e-waste, construction and demolition waste and other inert materials. Sodium silicate, which is a by-product of the e-waste recycling process, is added to the geopolymer mix to make solid, robust blocks that are 90 per cent more environmentally friendly.

Our Impact

Virtus Concrete carried out a carbon assessment of their novel concrete block in collaboration with Lancaster Environment Centre. This study demonstrated that one Virtus geopolymer concrete mix block, can achieve carbon dioxide emission savings of 105.4 kg compared to that of a standard concrete block.

Every year, Virtus Concrete produces about 7,500 Blockwalls (measuring 1600 X 800 X 800 mm) from its facility in the UK and provides a sustainable alternative for the construction and infrastructure industries. These blocks are also a cost-effective alternative to comparable steel and soil reinforcements or conventionally reinforced concrete retaining walls which have a significantly higher environmental footprint.

Why Us?

Virtus Concrete have incorporated many different waste materials such as kiln ash into our geopolymer blocks, wherein the kiln ash replaces the fine aggregates in the mix. This mix reduces the dependence on landfills for disposal of municipal waste and also replaces aggregates that would otherwise be mined.

By producing green infrastructure the company aims to contribute to saving the environment and continue generating positive social impact helping the community through meaningful job creation and skill development in the communities wherever they operate.