Plastic Waste

Who are we?

In order to tackle the growing plastic pollution issue, Blue Planet provides a comprehensive and sustainable solution by converting waste plastic into valuable energy and material outputs. The technology processes a wide range of plastics, including thin-film and low- grade plastic, by using a Thermo-Catalytic Depolymerisation (TCD) process. This method reverses the plastic production process by cracking the long chains of polymer to produce useable fuel oil. The Blue Planet technology is based on pyrolysis which is a cost-effective method to process low- grade plastic waste into high-energy by-products. Pyrolysis thermally degrades the plastic component to produce oil and synthetic gas.

Our Technology

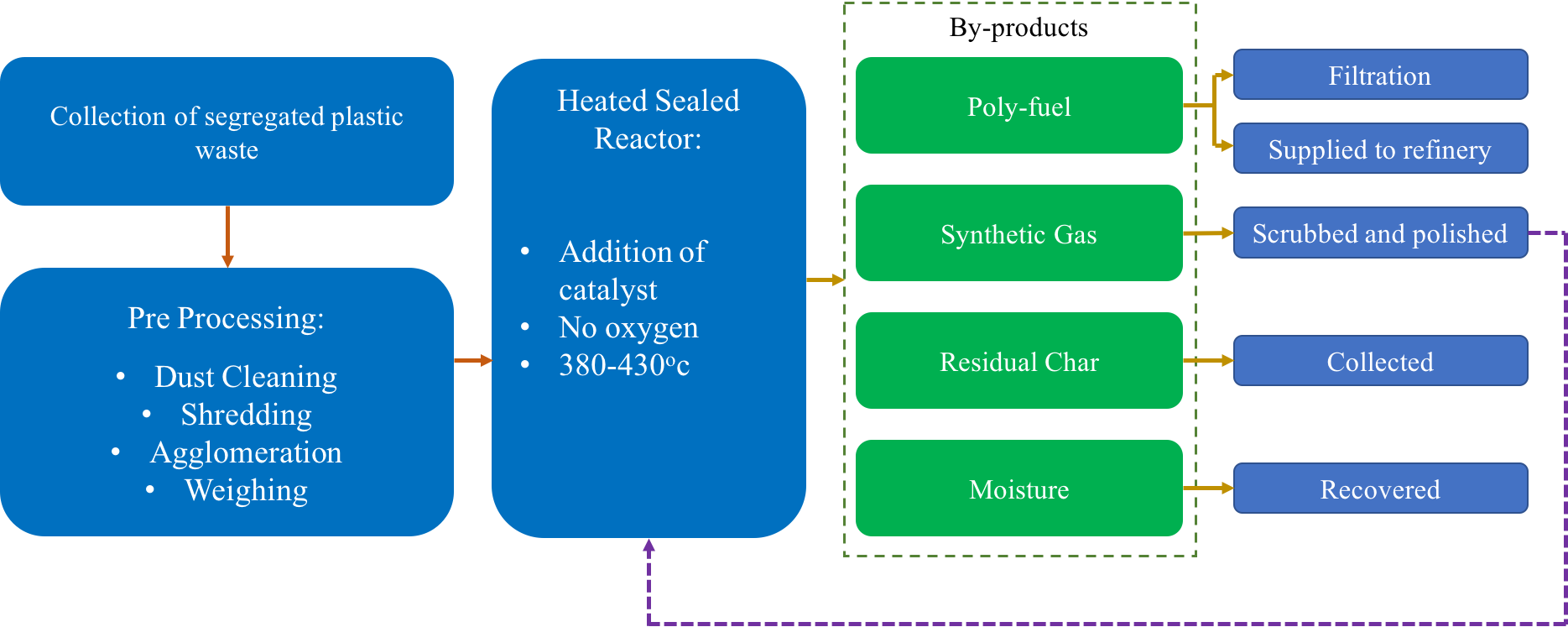

This oil may be used as a liquid fuel or returned for refining if there is available infrastructure to support such a synergy. Our depolymerisation technology involves the conversion of a rejected waste material into high-value liquid energy carriers. Furthermore, the fuel resulting from the process is sulphur-free and chemically pure. The TCD process is conducted within a heated sealed reactor. This reactor is loaded with the cleaned and shredded plastic which is then heated to a certain temperature. Inside the reactor, a catalyst helps in cracking the long chains of polymers in the absence of oxygen to produce hydrocarbon vapours. In the sealed reactor, the heat output is monitored to maximize the consistency of the fuel and to maintain high-quality outputs.

Our Process

The unit is operated in a batch-type process that takes between 3 to 7 hours to complete the TCD cycle based on the capacity of the installed machine. The temperature for plastic depolymerisation ranges between 380 – 430oC, during which the hydrocarbon vapour and synthetic gas are produced. Following the depolymerisation, the release is condensed which produces the synthetic gases and poly-fuel. It is critical that all technologies adopted by Blue Planet have a positive environmental impact. For this, we ensure that our depolymerisation solution is an emission-free process, creating the possibility for safe and effective processing of plastic waste by converting them into products of commercial value and applications.

Why Us?

The potential environmental benefit of plastic-derived fuels is also increased as the oil made from this process is a clean-burning fuel due to the low sulphur content of plastics. Blue Planet’s plastic-to-fuel solution, when applied on a larger scale, also provides another significant benefit. Due to the unpredictable change of energy prices and adverse forecast of the global economy, increasing efforts are being made to substitute raw fossil fuels with various other sources for the production of energy. Blue Planet technology has the capability to provide a substitute derived from upcycled low-value plastic.